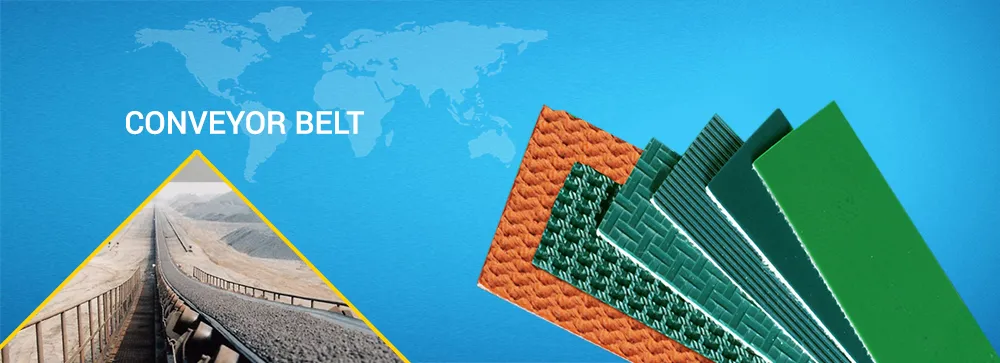

Conveyor Belt Manufacturer in India We are leading a top manufacturer, supplier, and exporter of conveyor belts, supplying a large selection of excellent-performing conveyor systems for a range of industries. Our team of conveyor belts is perfectly engineered to assure trustworthy, successful, and fast handling of materials in many kinds of applications.

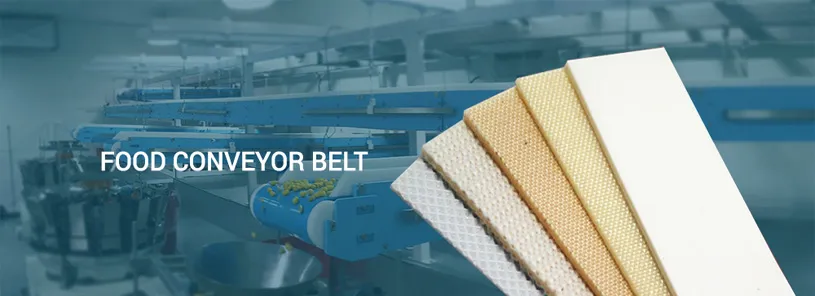

Our conveyor belts are commonly used in many different kinds of industries, including food processing, pharmaceuticals, packaging, mining, cement, and chemical plants. They improve worker productivity and improve production. We offer belts that are designed for outstanding resilience, adaptability, and durability as we are one of India's best-known conveyor belt manufacturers. To handle large loads, abrasion, and harsh working circumstances, each conveyor belt is made using cutting-edge technology and excellent-quality materials. Rubber conveyor belts, temperature-resistant belts, fire-resistant belts, and industrial-grade belts are all part of our extensive selection of conveyor belts, which can be specific in respect to length and requirements

Offers a wide range of Stylish Quality factors. Since its founding in 1993, Shetty Enterprises has developed into one of India's most estimable and secure suppliers and conveyor belts and conveyor system manufacturers of conveyor belts. Our specialty is supplying superior conveyor belts that are made to be largely effective, flexible, and effective in numerous kinds of operations in assiduity. .

The range we offer features rubber conveyor belts, heavy- duty belts, heat- resistant belts, fire- resistant belts, and marketable- quality conveyor belts, all of which are constructed using the stylish corridor and slice- edge technologies. Each belt has been precisely constructed with strong factors to give successful substance operation and a long service continuance.

Our conveyor belts can be designed to satisfy the different requirements of our guests and are manufactured in keeping with dependable norms and guidelines. These accoutrements are considerably employed in a wide range of diligence, similar as cement, mining, sword, food product, quilting, and transportation.

Our conveyor belts increase affair and effectiveness in every operation due to their perfect evaluation, robust manufacturing, amazing stir, and running easily.

One of the top exporters of rubber conveyor belts in India, Shetty Enterprises provides high- end conveyor results that are reckoned upon by businesses worldwide. With decades of manufacturing and exporting experience, we're experts at creating robust and effective rubber conveyor belts that can serve dependably indeed in the most trying circumstances.

Our rubber conveyor belts have superior resistance to wear, bruise, impact, and heat because they're made of outstanding synthetic as well as natural rubber composites. These belts are extensively used in the mining, cement, sword, toxin, food processing, and packaging sectors for safe and effective transfer of accoutrements .

A top manufacturer of conveyor belt accessories in India, We give a full line of ultraexpensive corridor intended to ameliorate the effectiveness, robustness, and performance of conveyor systems. With times of experience in the conveyor business, we offer reliable and nicely priced accessories that guarantee trouble-free and effective material handling operations.

Conveyor belt fasteners, breakers, pulleys, loafers, belt cleansers, skirt rubbers, impact beds, and tracking systems are all part of our product line, which is produced exercising high- quality accoutrements and slice- edge engineering styles. Each attachment is perfect for sectors including mining, cement, sword, quilting, food processing, and logistics since it's made to endure big loads, grueling conditions, and nonstop operation.

A well- known patron of conveyor belt fasteners in India, We provides an expansive range of strong, exceptional fasteners for secure conveyor belt joining and keep. With times of experience and engineering moxie, we deliver fastening results that assure strong connections, easy installation, and extended belt life.

Offering superior belts made for perfect shadowing, fluid operation, and outstanding effectiveness, Shetty Enterprises is the leading manufacturer and supplier of conveyor belts with companion in India. For operations that call for exact belt misalignment and smooth movement, our guided conveyor belts are perfect for operations that lower time-out and boost effectiveness during operations.

A conveyor belt is a continuous moving belt used for transferring products or services from one place to another. It comprises rubber, fabric, metal, or other strong materials. It is the most important component of a conveyor system, which is commonly used in sectors like construction, manufacturing, mining, wrapping, logistics, and food processing.

conveyor Belt is the carrying medium of a belt conveyor system, one of the types of conveyor systems that are accessible today. The conveyor system is one of many types of conveyor systems. There are two main industrial classes of conveyor belts: one is general material handling and the other is bulk material handling. Moreover, if you are in need of a conveyor belt or a conveyor system that includes conveyor belts, then Shetty Enterprise offers the conveyor belt consultations with an experienced member of the team who listen to your ideas and, as per your needs, we will design a suitable bespoke solution for your conveyor belt.

Conveyor belts can be used to transport products in a straight line or through changes in elevation or direction. For conveying Bulk Materials like Grains, Ore, Coal, Sand etc., over gentle slopes or gentle curvatures, a troughed belt conveyor is used.

The below mentioned are the few hot types of ConveyorBelts

Conveyor belts are simple but extremely successful mechanical pieces that have converted how accoutrements are transported in numerous different sectors. Conveyor belts were first employed in the ore mining sector in the 19th century to efficiently and fleetly load the train vehicles. They've developed over time into essential rudiments in sectors like construction, manufacturing, logistics, and food processing.

A conveyor belt works on disunion. It comprises of a belt fitted further than at least two rotating breakers. The corrosion between the belt and breakers makes the belt advance or in rear. Along these lines, rotational movement of the comber is converted to direct movement of the belt. Conveyor Belts are unnaturally wide belts added in a circle to at least two turning rotors driven by machines. The circle is the real conveyor belt, and is for the utmost part made of at least two layers of elastic, one subcaste to give shape and structure to the belt and one to enable it to transport its mound securely. This conveyor belt is for the utmost part added to two bus, called rotors, which are spun by machines. The conveyor belt has enough rubbing amongst it and the rotor that it adheres to this rotor.

To produce a huge multifariousness of the conveyor belt we're using the stylish quality of accoutrements . The general idea below shows the introductory main material employed for manufacturing the conveyor and processing belts. We're using the accoutrements from essence to fabrics, a variety of accoutrements , depending in the customer’s purpose.

| Material | Application |

|---|---|

| High Carbon Steel | Baking and Food Processing Industries |

| Stainless Steel and Stainless Alloys | Plastic, Lamination, Wood, Rubber, Chemicals, and Even Food Production industries |

| Rubber | Food Production Industries |

| Plastic | For cooling chambers and other low-heat applications. |

| Polypropylene | Packaging, Textiles, Stationery, Plastic parts and Reusable containers of various types, Laboratory equipment, Loudspeakers, Automotive components, and Polymer banknotes. |

| Teflon-Coated Fabric | For Baking or Drying applications in food production. |

| Woven PVC | For Baking or Drying applications in food production. |

| Aramide PTPA | Aerospace and Military applications |

| Ethylene-propylene-(diene)-terpolymer EPDM | Electrical cable-jointing, Roofing membranes, Geomembranes, Rubber mechanical goods, Plastic impact modification, Thermoplastics, Vulcanizates, and many other applications. |

| Natural Fiber | Textile Industry |

| Natural Rubber | Sugar Mill Application |

| Nitrile-butadiene Rubber | Automotive, Nuclear and Aeronautical industry |

| Polyester | Paper mills, Steel industry, Automotive industry, Fertilizer industry, Pharmaceutical |

| Polyvinylchloride | Light, Medium and Heavy Industries, including electronics, Food & Parma, Bakery & Confectionary, Meat & Poultry, Packaging, Wood working, Glass, Ply & Board, Automobile, Health & Fitness |

| Silicon Rubber | Automotive applications; Cooking, Baking, and Food storage products; Apparel such as Undergarments, Sportswear, and Footwear; Electronics; Medical devices and Implants; and in Home Repair and Hardware, |

Deciding your adventure degree and spending plan is critical. To enable you to begin, then are some broad case conveyor and sortation conveyor pricing.

stiut introducing ll, you've presumably allowed

aboconveyor or refreshing your present conveyor frame, If your association is looking to increase the effectiveness in its storehouse or distribution center. Assuming this is the case, the conveyor assessing you get will shift in light of your requirements and the extent of the undertaking; be that as it may, beneath are some broad valuing rules to enable you to decide your adventure spending plan.

We need to make a couple of suppositions to give a morning stage to each kind of conveyor, so in the event that you might want a further correct hand, please do not vacillate to reach one of our business contrivers, and they can enable you to decide the correct conveyor for your fabrics and also the sum you'll bear

Shetty Enterprise is a leading manufacturer and supplier of conveyor belt. We are manufacturing the conveyor belts in its own production facilities for application in diverse sectors, including independent distributors, confectionery companies, maintenance departments and OEM end users. We are supplying the Conveyor Belts which are manufactured utilizing material such as PVC, PU, Polyethylene, felt and silicones. Further the benefits and support facilities offered by us are mentioned below: